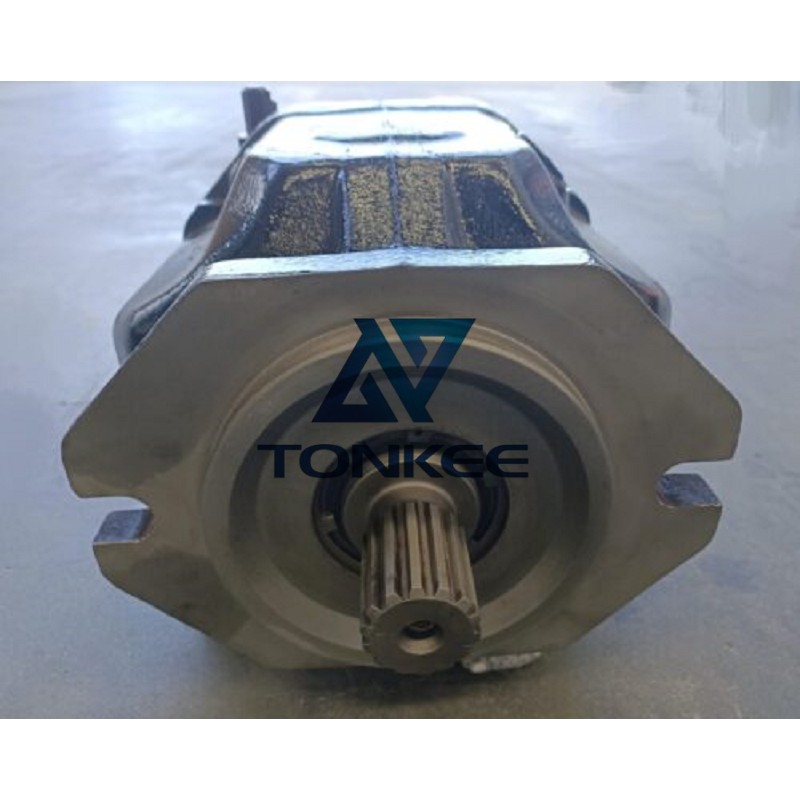

Part Number: VOE - 11172710. This unique identifier is used to precisely identify the hydraulic pump rebuild kit for Volvo L70E and L90E models. It ensures accurate ordering, inventory management, and compatibility within Volvo's equipment systems.

Applicable Models: Specifically engineered for the Volvo L70E and L90E loaders. These loaders rely on the hydraulic pump for various functions such as lifting, tilting, and steering operations. The rebuild kit is designed to restore the hydraulic pump's performance to its original or near - original specifications.

Rebuild Components

Wear - Prone Parts Replacement

Pump Shaft: The kit includes a high - quality replacement pump shaft. The shaft is made from a durable alloy steel, typically with a hardness of [X] HRC (Rockwell Hardness C - scale). This hardness ensures resistance to wear and fatigue, which are common issues due to the continuous rotation and loading in the hydraulic pump. The shaft has a diameter of [shaft diameter in mm] with a tolerance of ± [tolerance value in mm], ensuring a precise fit within the pump housing and other components.

Vanes: New vanes are provided in the rebuild kit. These vanes are manufactured from a special composite material that offers a balance of strength and flexibility. They have a thickness of [vane thickness in mm] with a tolerance of ± [vane thickness tolerance in mm]. The vanes are designed to slide smoothly within the rotor slots and create the necessary pressure differentials for hydraulic fluid displacement. Their surface finish has a roughness of Ra [roughness value in μm] to minimize friction and wear.

Rotor: The replacement rotor is crafted from a high - grade cast iron or alloy. It has a carefully machined surface with a flatness tolerance of ± [flatness tolerance value in mm]. The rotor's internal slots, where the vanes are housed, are machined to precise dimensions. The slot width is [slot width in mm] with a tolerance of ± [slot width tolerance in mm], ensuring proper vane movement and efficient hydraulic operation.

English

English بالعربية

بالعربية